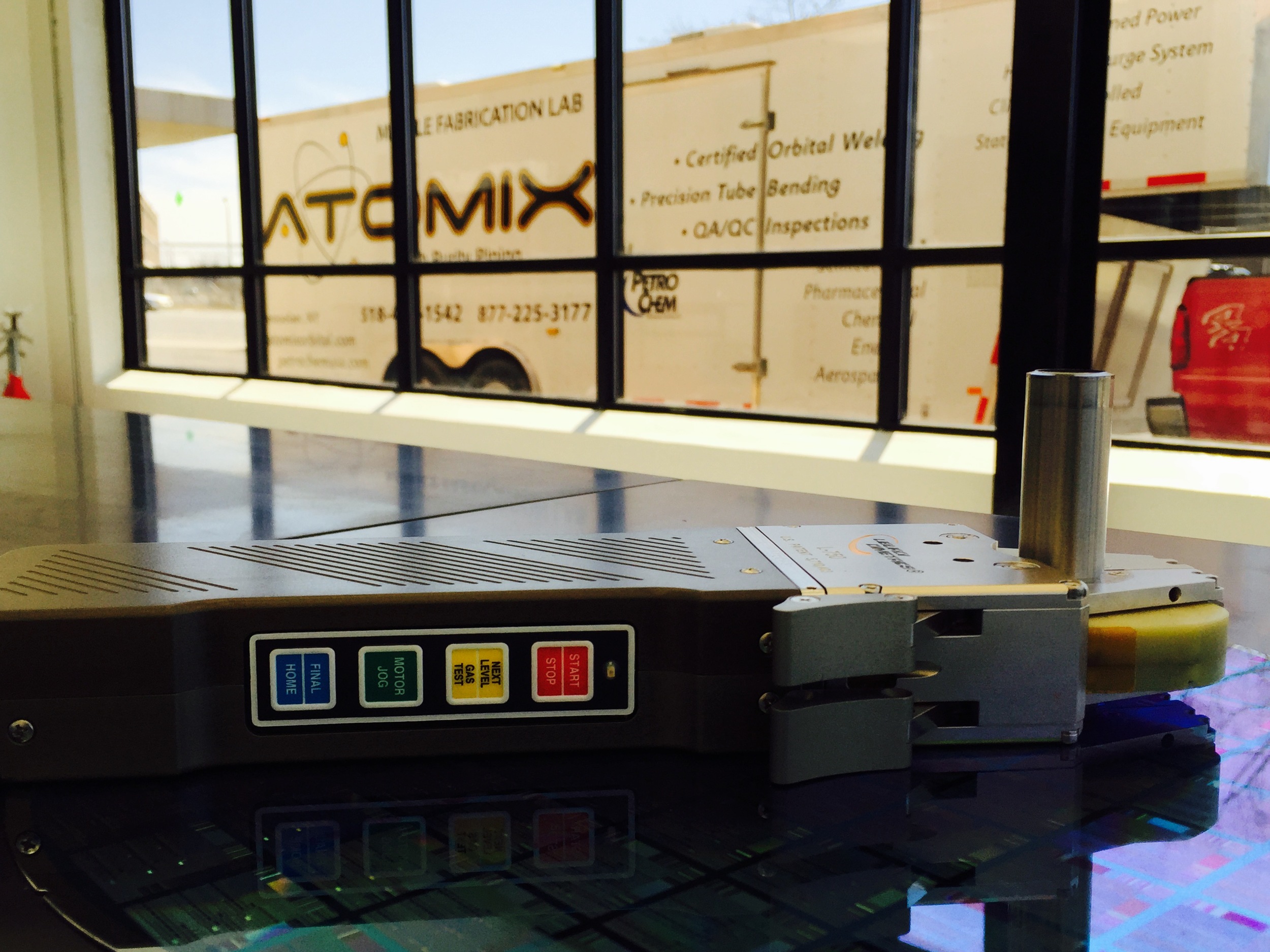

Certified Orbital Welding

Certified Orbital Welding

Certified Orbital Welding

Certified Orbital Welding

ATOMIX™ is a member of the National Certified Pipe Welding Bureau and employs welders certified in accordance with Section IX of the ASME Boiler and Pressure Vessel Code. This assures high integrity and repeatable welds that exceed tests, documentation requirements, and final inspections.

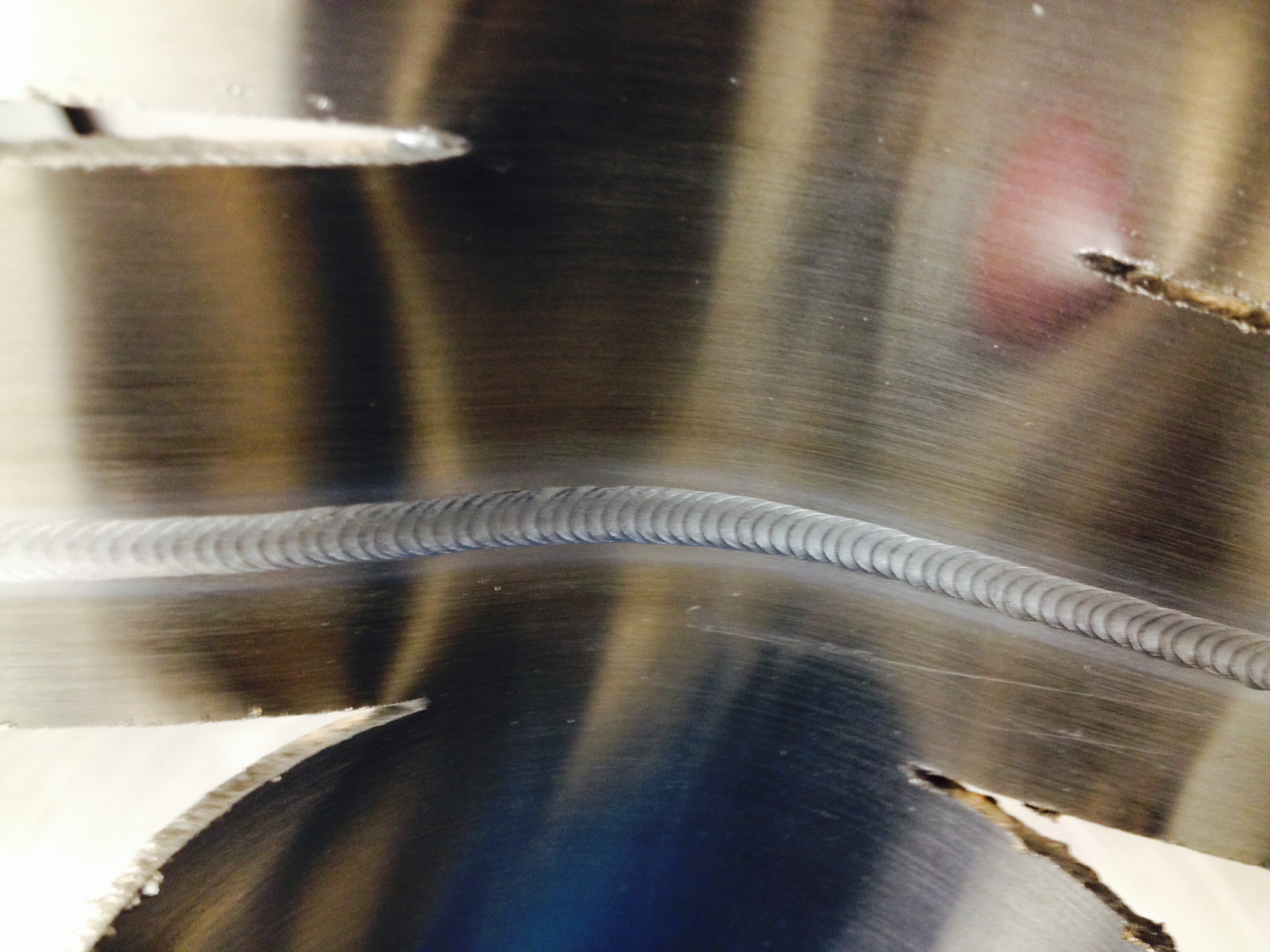

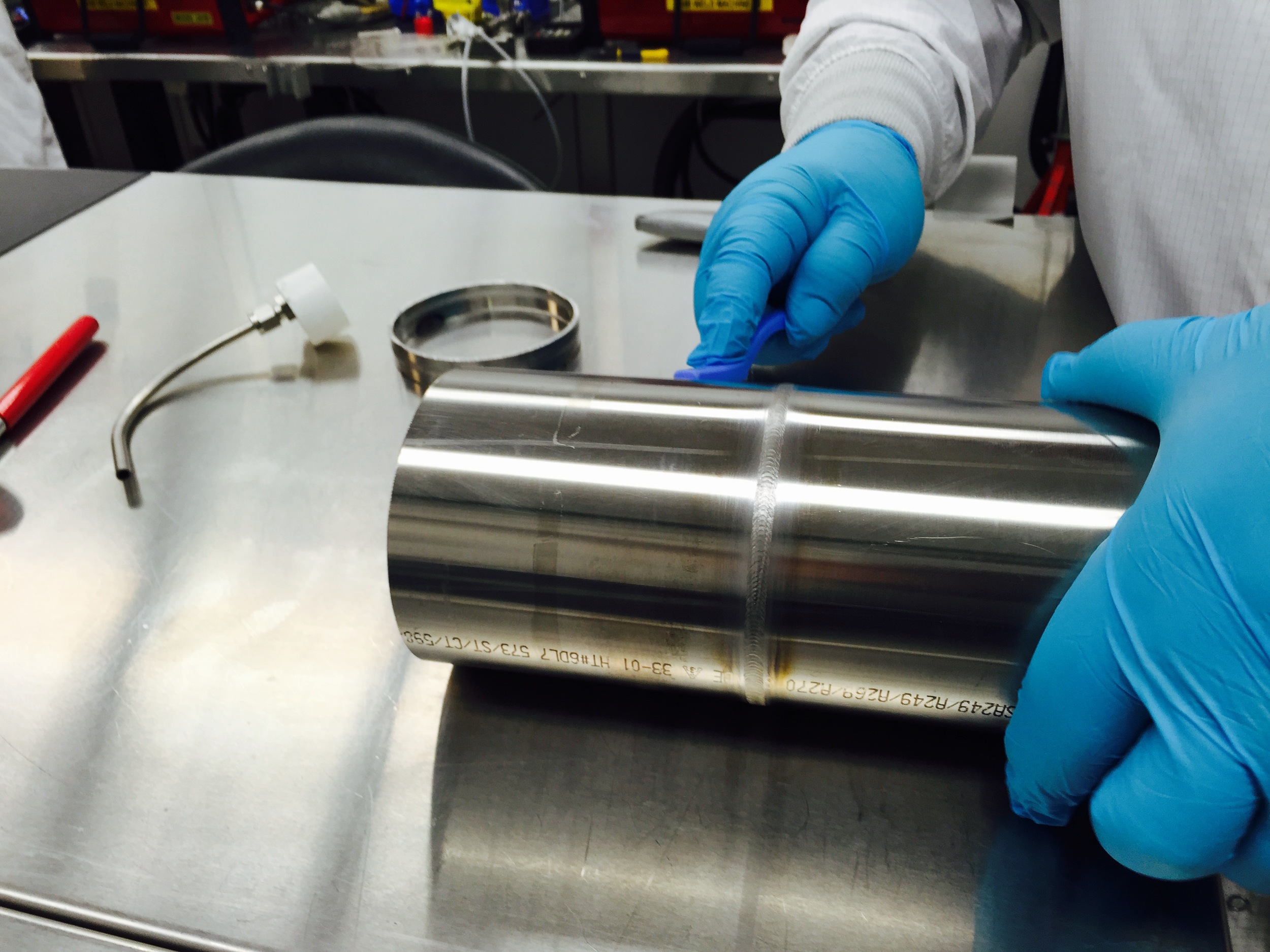

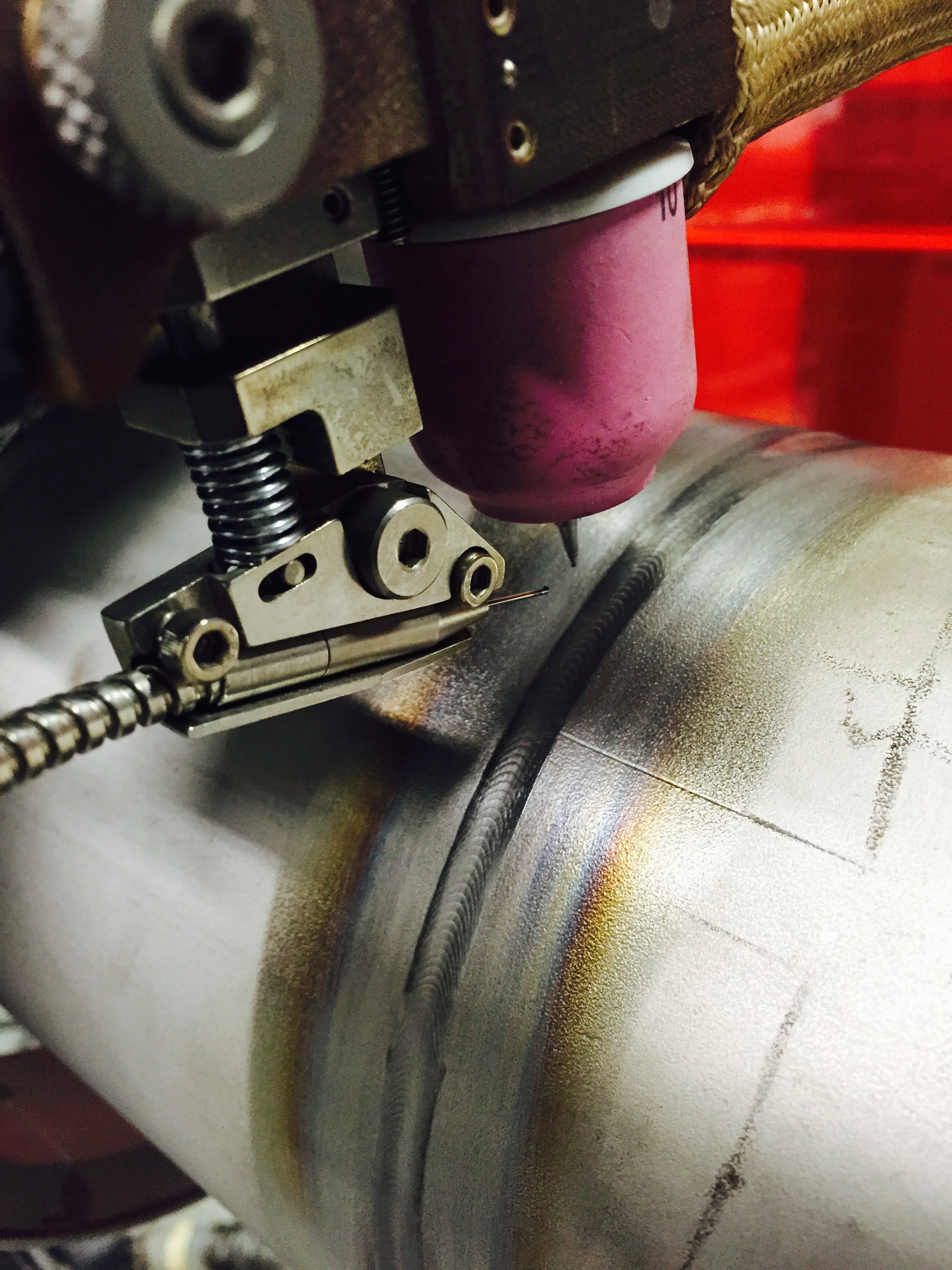

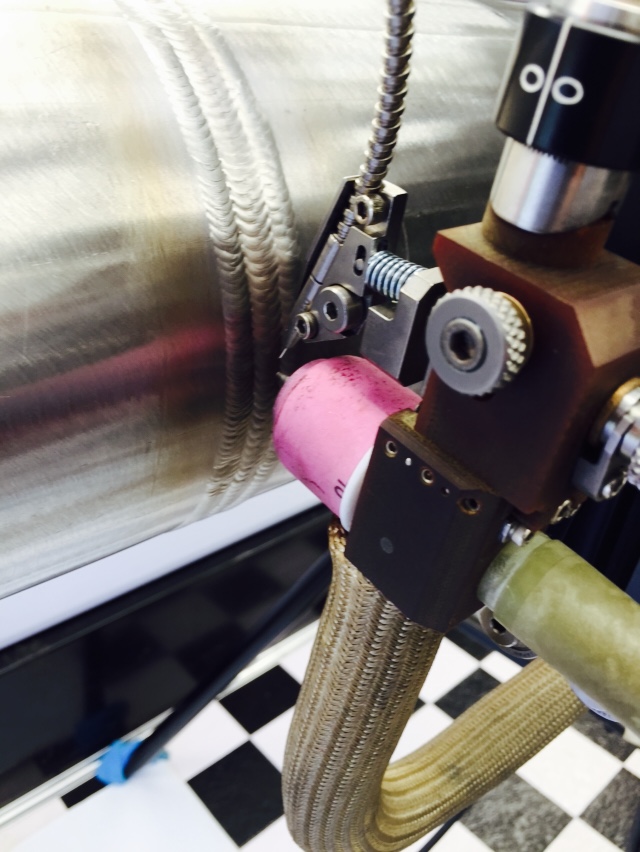

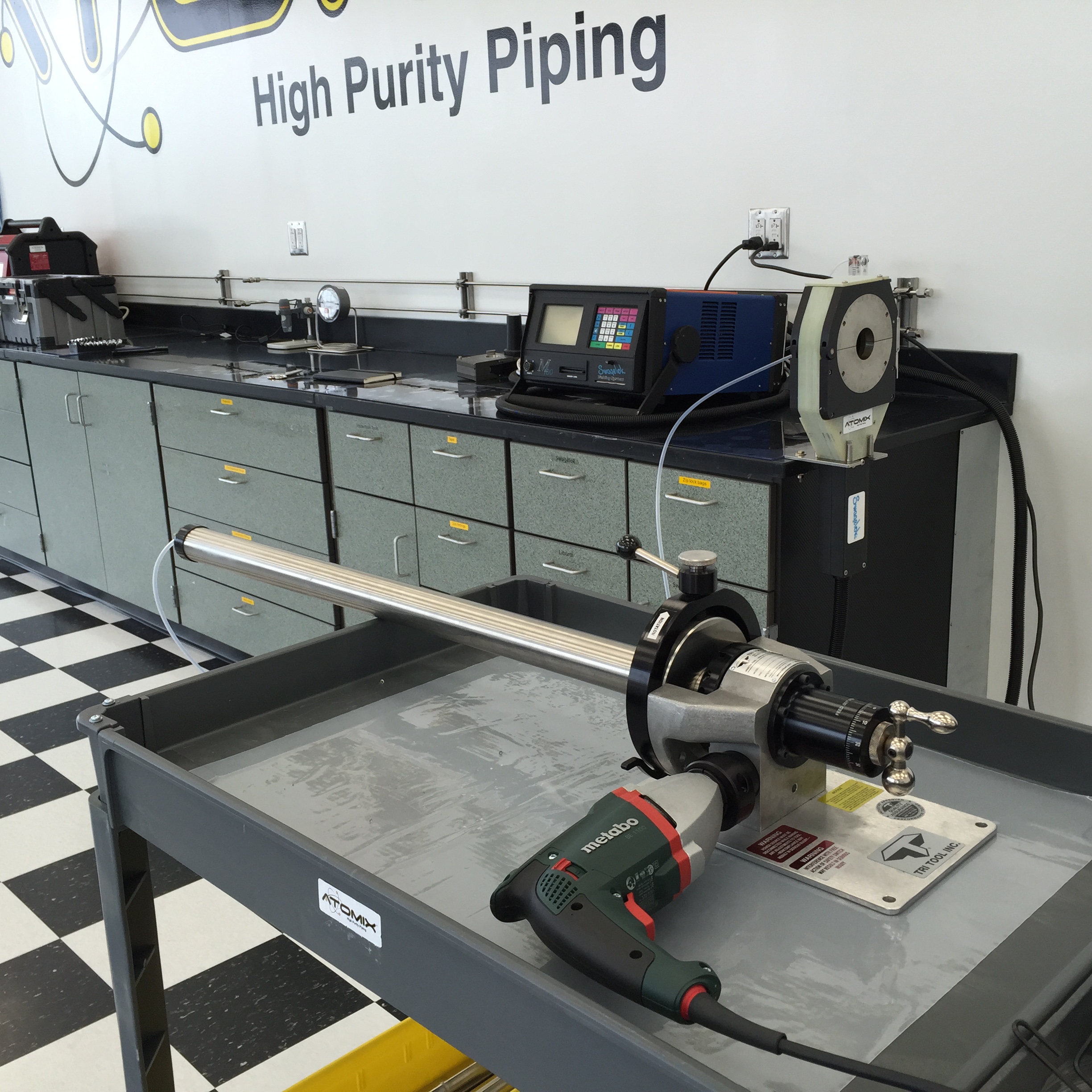

Stainless Steel Tubing

Stainless Steel Tubing

Stainless Steel Tubing

Stainless Steel Tubing

Stainless Steel Tubing is the most common application for orbitally welded systems. ATOMIX™ provides a full range of OD capabilities for both tubing end prep and welding. ATOMIX™ details tubing systems to combine orbital welding with precision bending to optimize both flow and purity performance of the operating system.

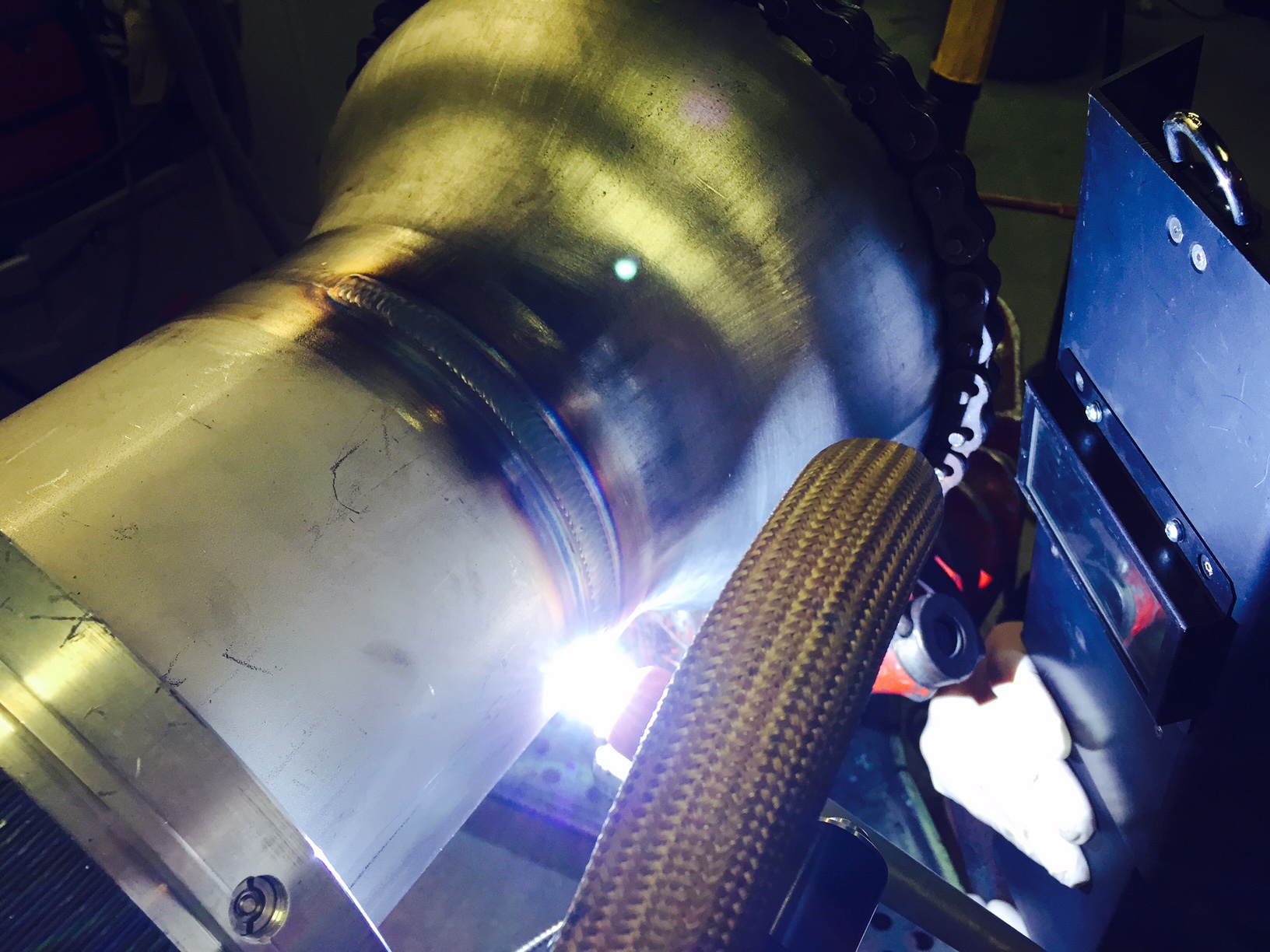

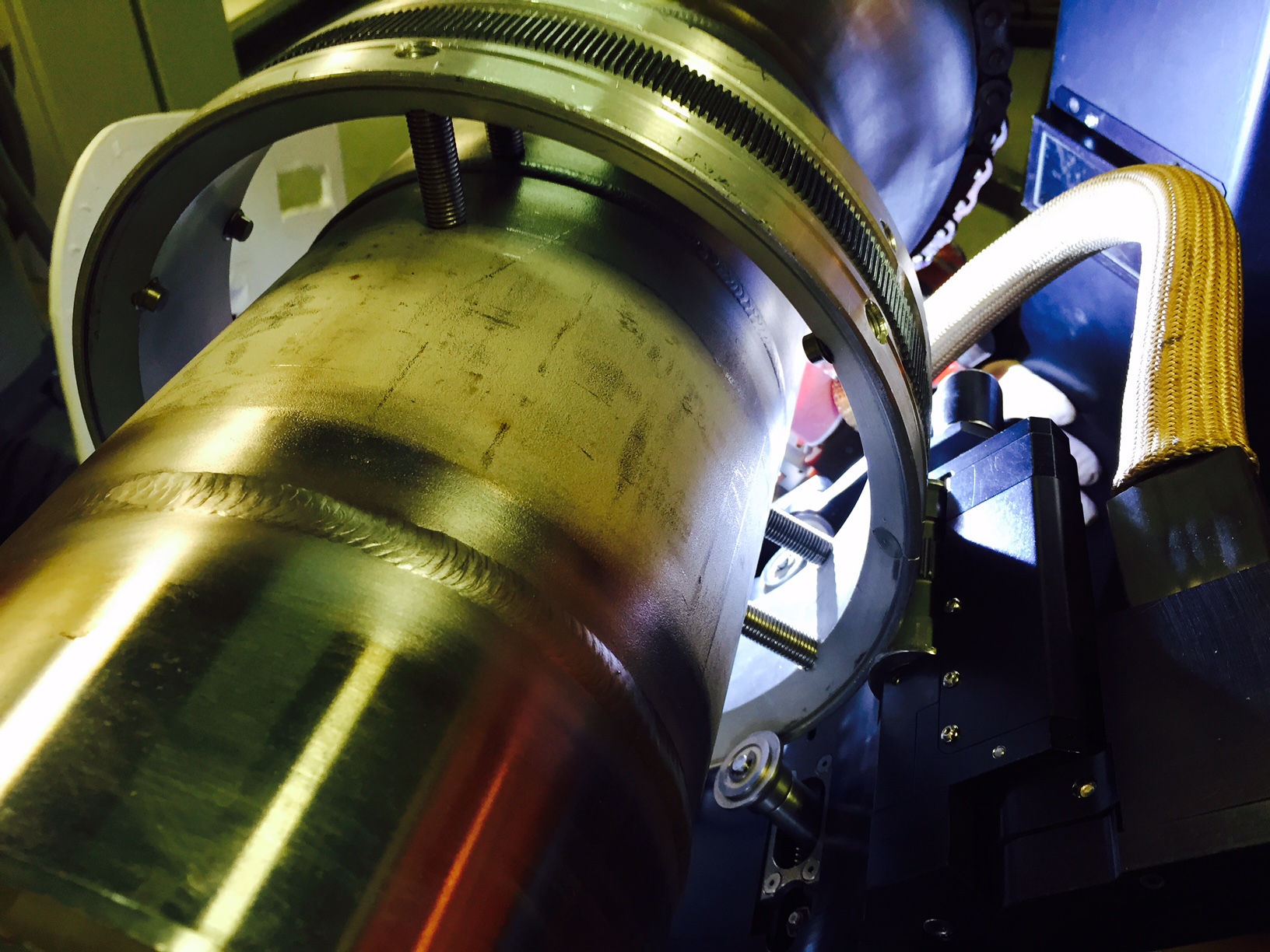

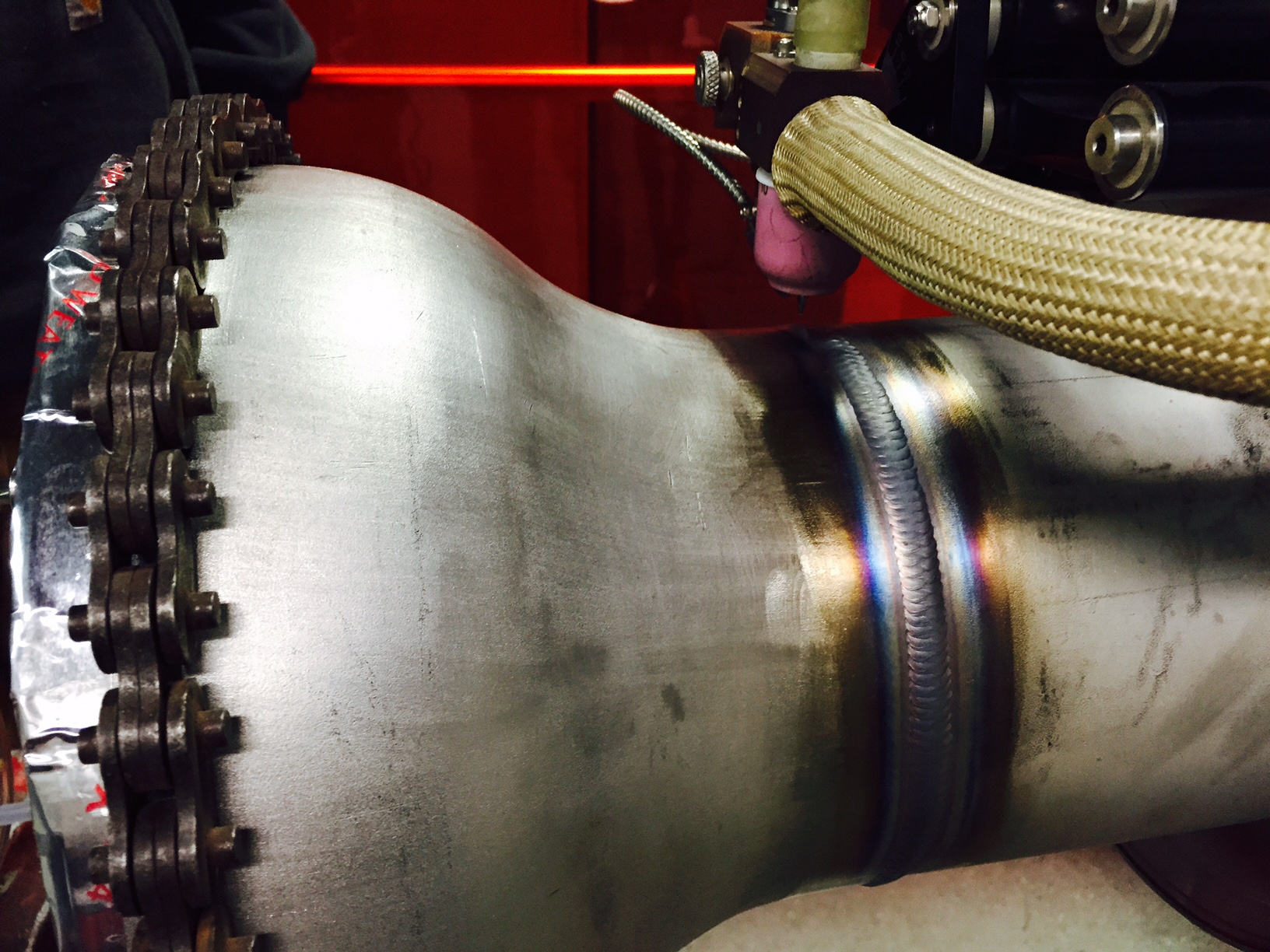

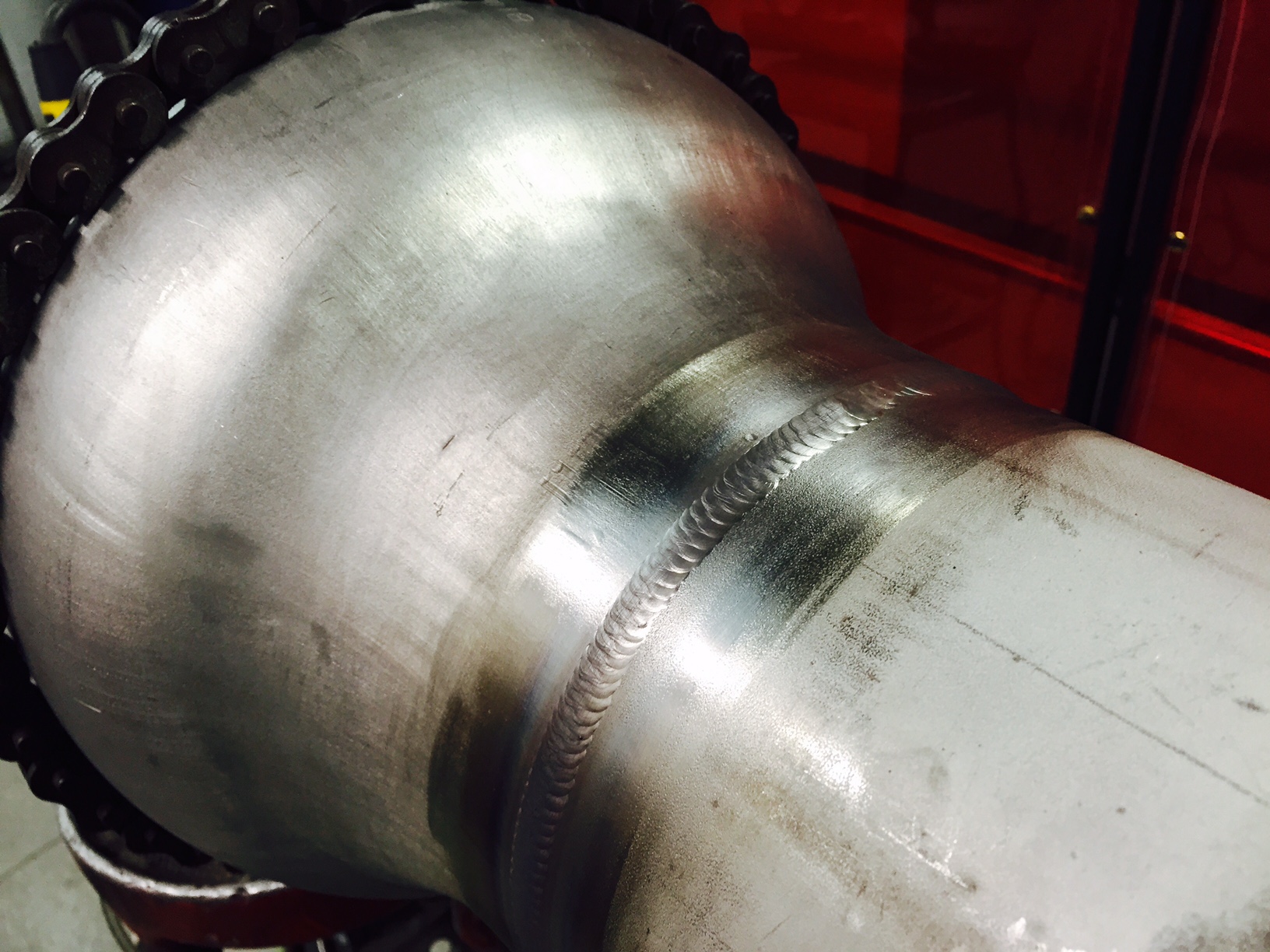

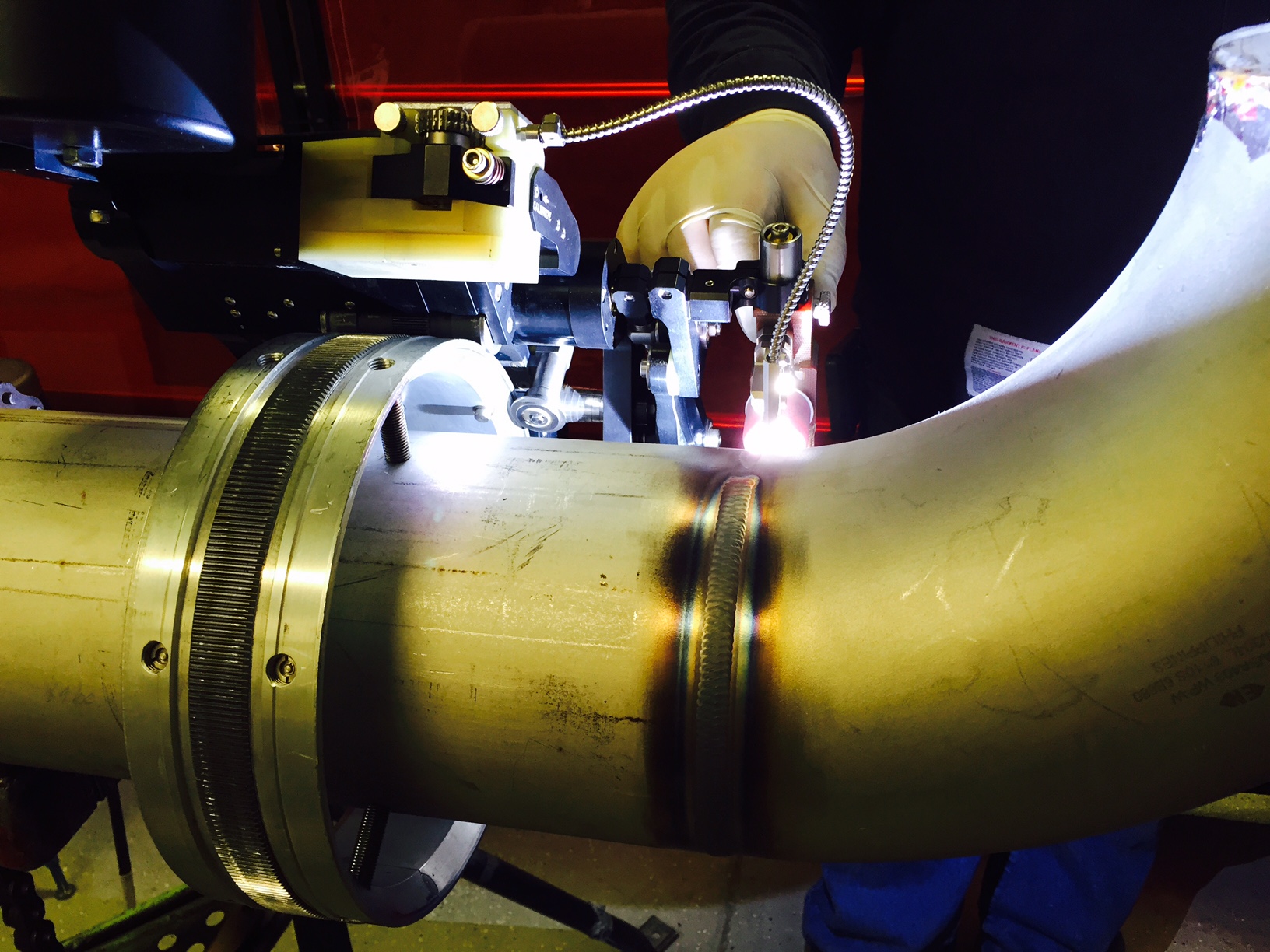

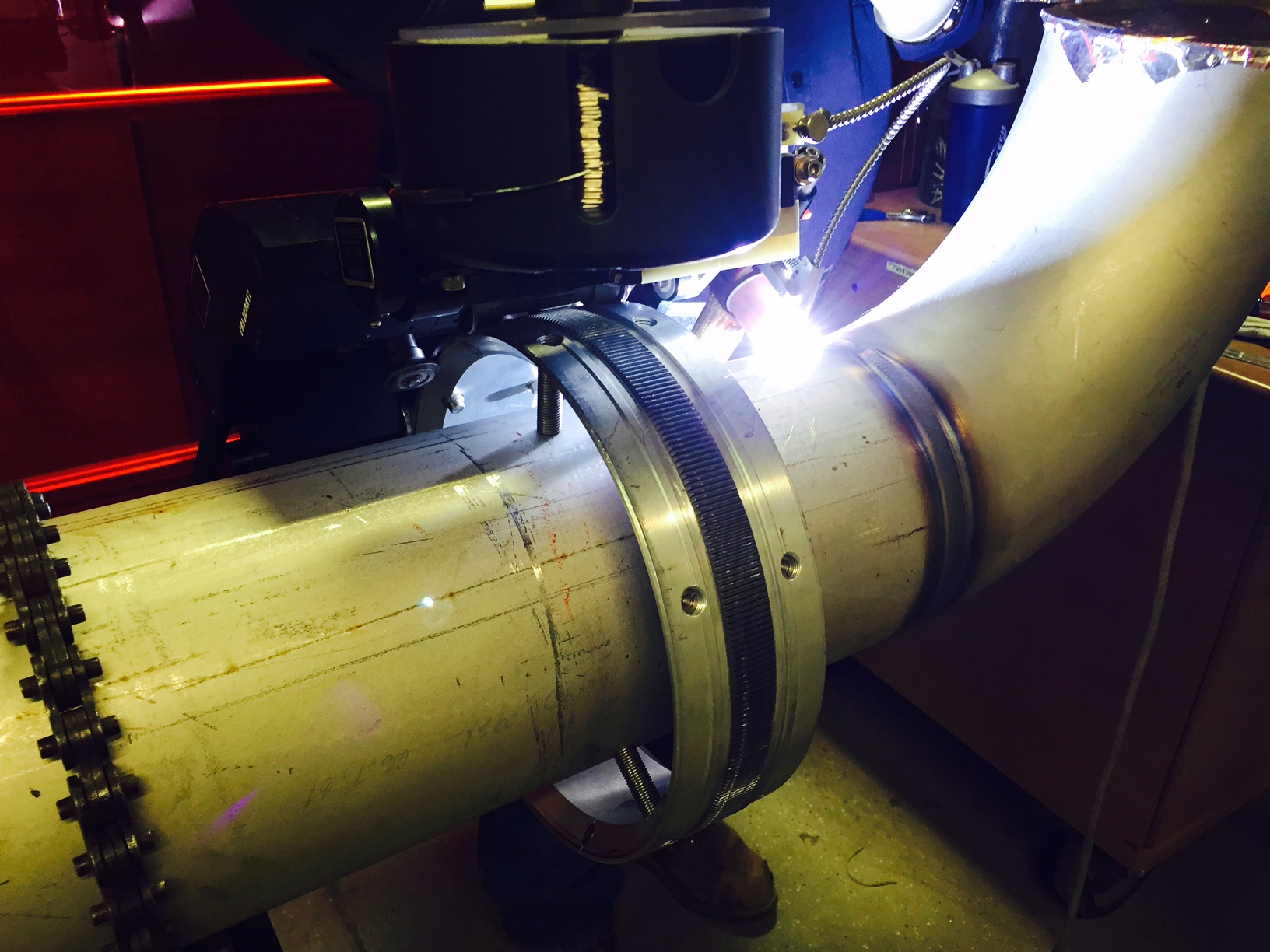

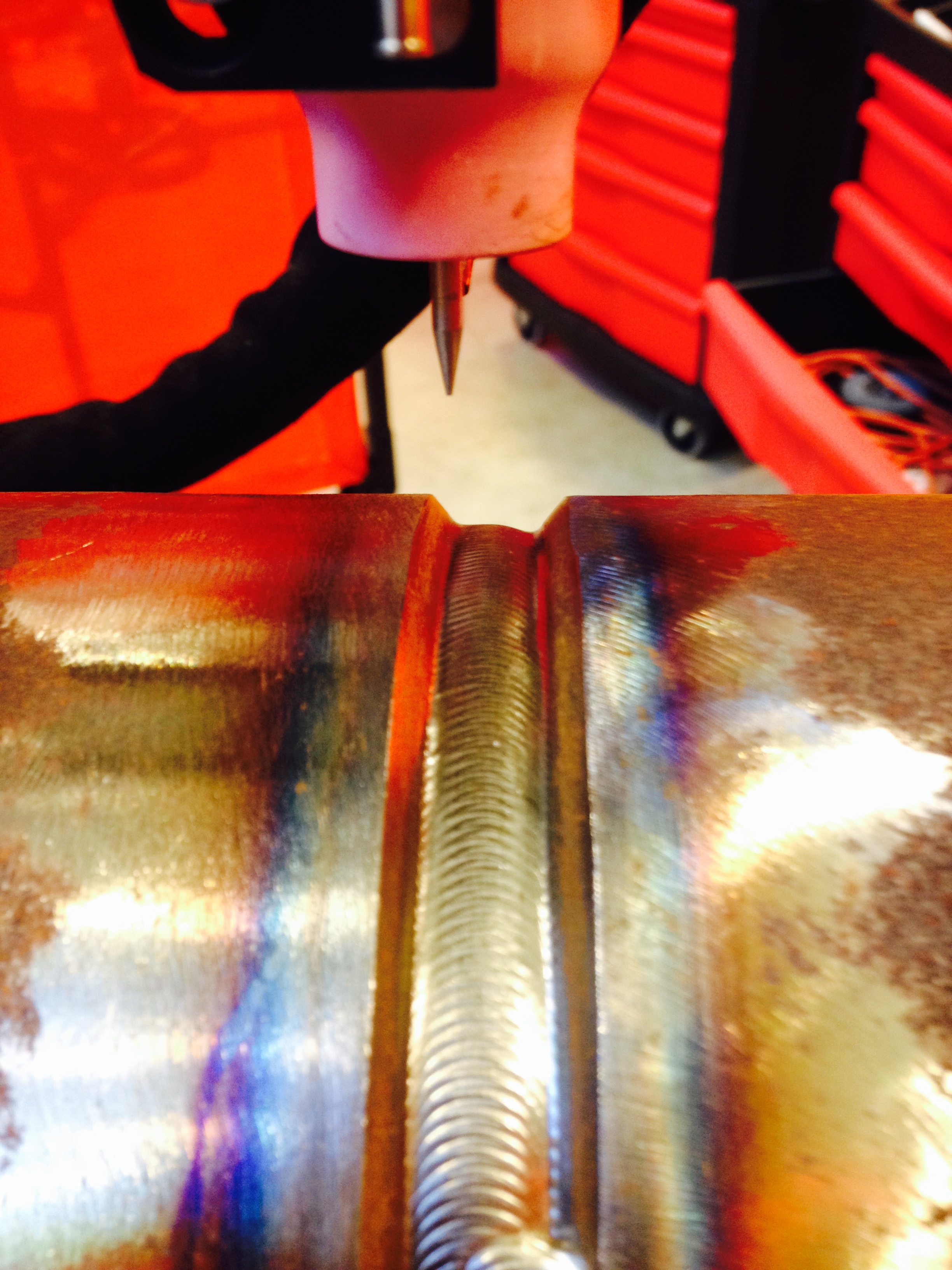

Stainless Steel Pipe

Stainless Steel Pipe

Stainless Steel Pipe

Stainless Steel Pipe

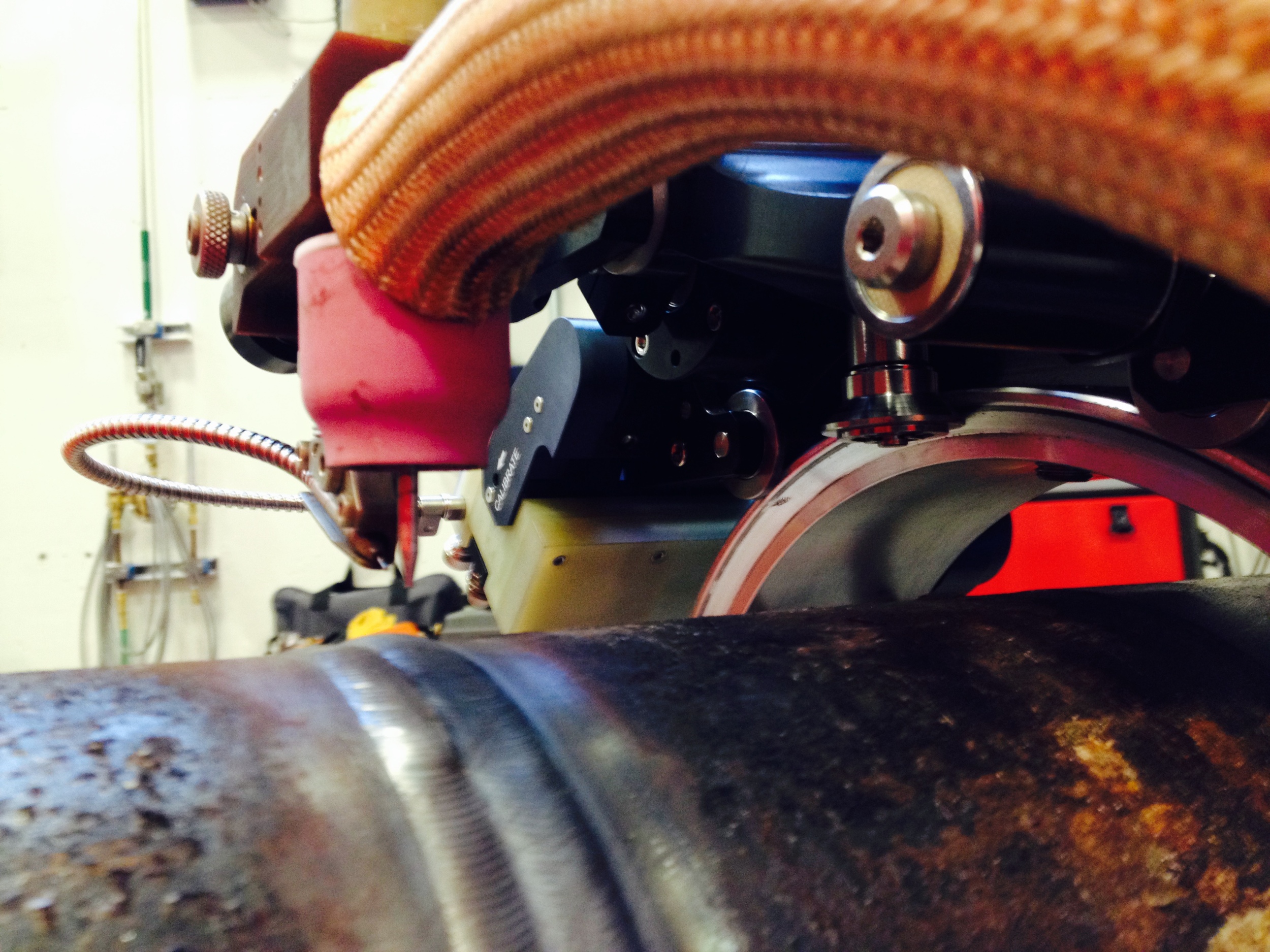

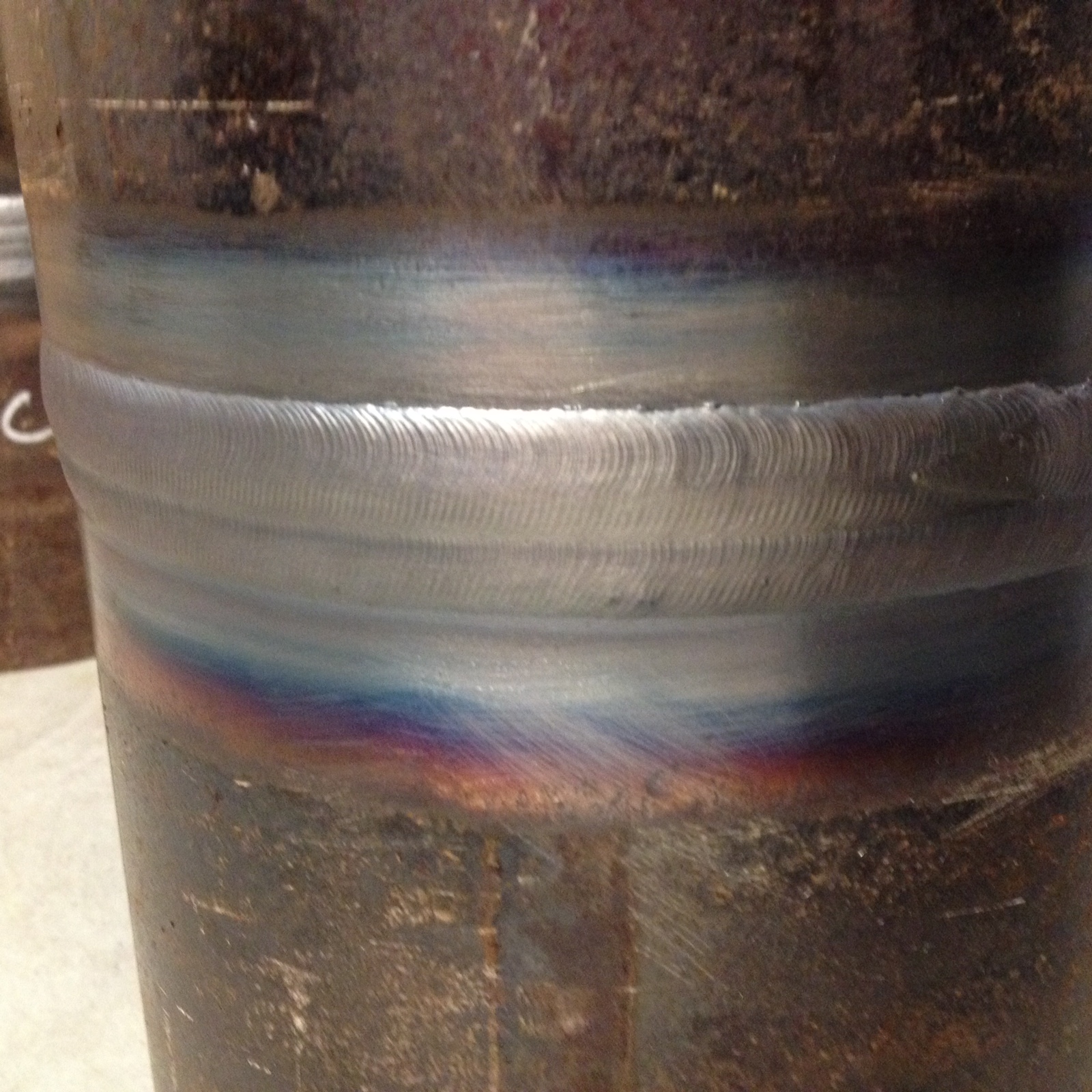

Stainless Steel Pipe can now be orbitally welded not only in the fab shop, but in-position, and at your facility! ATOMIX™ offers a full range of orbital welding solutions for standard and heavy wall pipe by using automatic orbital wire feed TIG equipment for Schedule 5, 10, and 40 stainless steel piping.

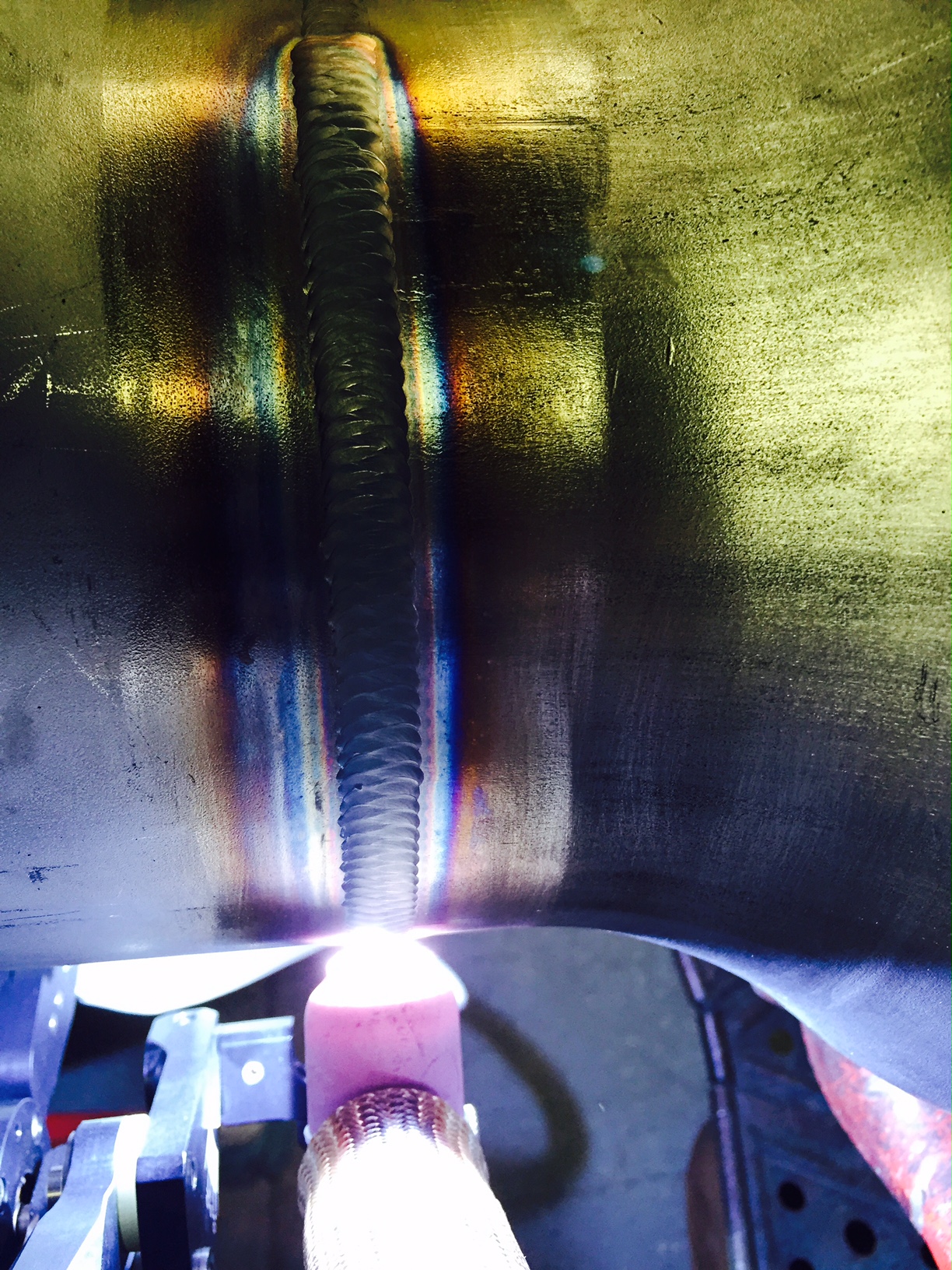

Carbon Steel Pipe

Carbon Steel Pipe

Carbon Steel Pipe

Carbon Steel Pipe

ATOMIX™ offers a full range of orbital welding solutions for standard and heavy wall pipe using automatic orbital wire feed TIG equipment for Schedule 40 carbon steel piping. Carbon Steel Pipe Pipe can now be orbitally welded not only in the fab shop, but in-position at your facility!

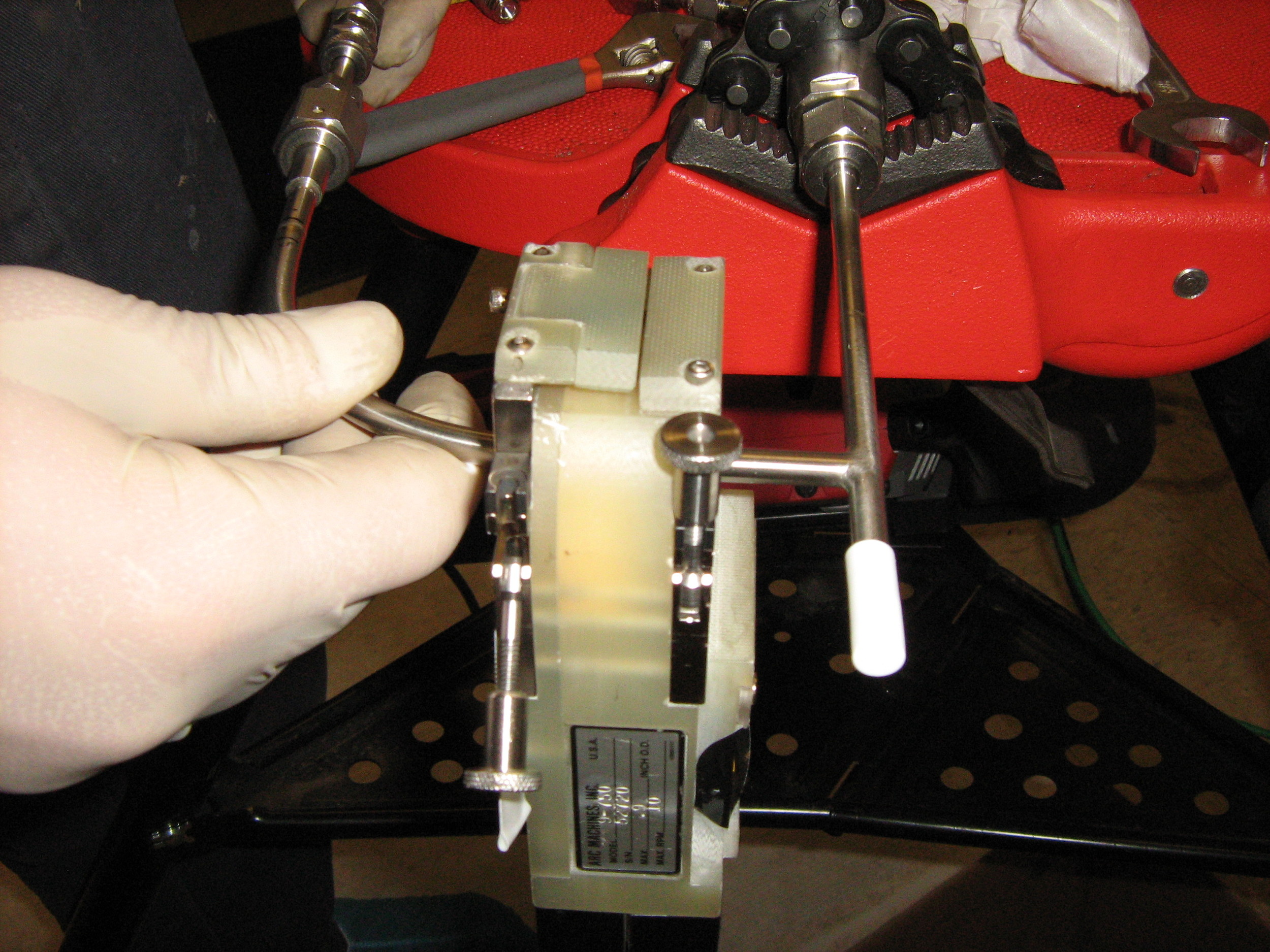

Vacuum Jacketed Piping

Vacuum Jacketed Piping

Vacuum Jacketed Piping

Vacuum Jacketed Piping

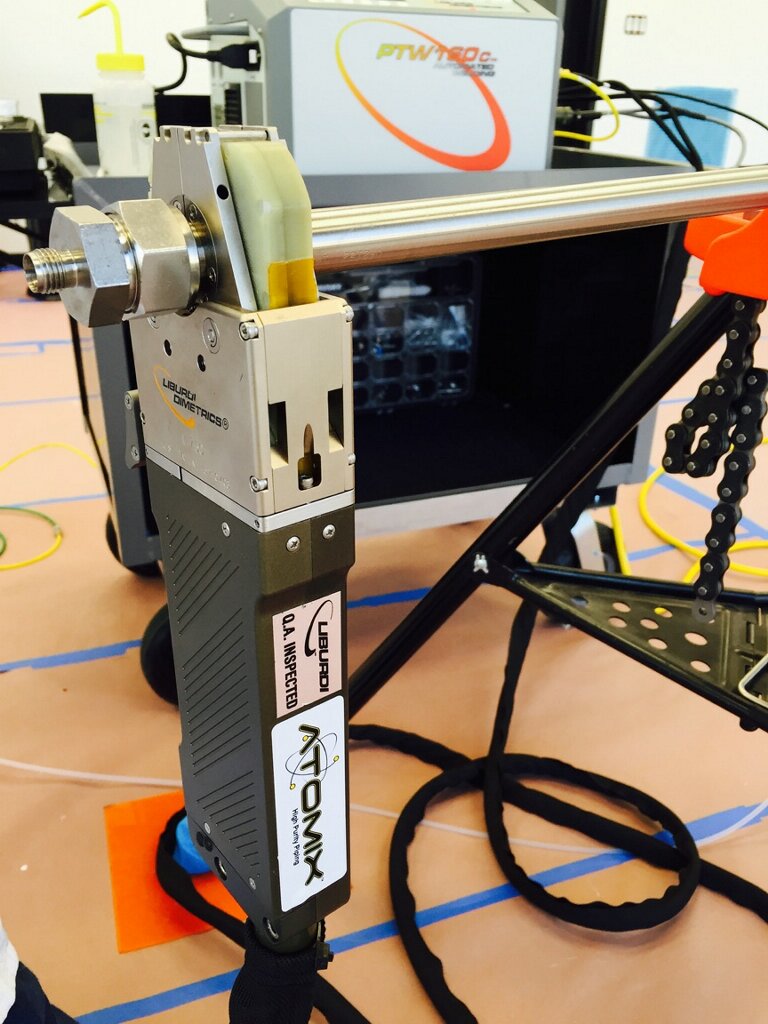

ATOMIX™ has state of the art welding technology, real time documentation methods simplify validation of bioprocessing systems.

ATOMIX™ has Liburdi real time data system that utilizes microprocessor technology and has the ability to monitor the welding process, capture and compile real time data, and transfer it to the system computer where it is formatted for statistical analysis.

Weld logs are maintained electronically and imported, then formatted for installation qualification. This supporting documentation is a must have for FDA documentation.

ATOMIX™ installs and maintains Vacuum Jacketed Piping for cryogenic gas delivery systems:

- Laboratory / Cryobiology

- Food / Beverage

- Electronics / Semiconductor

ATOMIX™ services include:

- Rigid and bendable VJP

- Transfer hoses

- Cryogenic system design

- 10 year warranty